Bearing internal clearance refers to the amount of space between the inner and outer raceways when one ring is held fixed. This small but crucial gap allows for smooth movement between the rolling elements and the raceway, ensuring proper function. Choosing the right clearance is essential because it directly affects the bearing's performance, noise level, and longevity.

Understanding internal clearance is key to optimizing bearing operation. Too little clearance can cause excessive friction and overheating, while too much can lead to instability and reduced load capacity. The ideal clearance depends on several factors, including the application, temperature, and load conditions.

Why Internal Clearance Matters

Bearing internal clearance plays a vital role in determining how efficiently a bearing operates. It influences whether the rolling elements move smoothly or start to slide, which can impact energy efficiency and wear. Proper clearance helps maintain even load distribution, reducing vibration and noise, and ultimately extending the bearing’s service life.

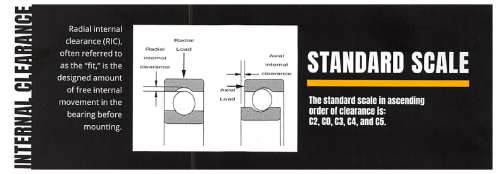

There are two main types of internal clearance:

- Radial Clearance: The movement perpendicular to the bearing axis.

- Axial Clearance: The movement along the bearing axis.

Radial clearance is calculated by measuring the average diameter of the outer raceway, subtracting the average diameter of the inner raceway, and then adjusting for the ball size. Axial clearance is typically about ten times the radial clearance value. These measurements help ensure the bearing functions properly under different operating conditions.

How Much Clearance Should You Use?

The ideal internal clearance is as small as possible—often just a few microns or even zero after assembly. However, this must be adjusted based on the specific needs of your application. Factors such as temperature, load, and speed all influence the required clearance. For example, high-speed or high-temperature environments may require more clearance to account for thermal expansion.

Selecting the correct clearance ensures optimal performance and minimizes the risk of premature failure. It also enhances efficiency and reduces maintenance costs over time.

C0 vs. C3 Clearances: What’s the Difference?

When choosing a bearing, you’ll often encounter two common clearance classes: C0 and C3.

- C0 (or CN): This is the standard clearance used in most applications. It is suitable for normal operating conditions and typical fits. C0 clearance is usually not marked on the bearing itself.

- C3: This offers a larger clearance than C0, making it ideal for situations where thermal expansion or special load conditions require extra space. C3 bearings are commonly used in high-speed or high-temperature environments.

Choosing the right clearance type ensures that your bearing performs reliably under the conditions it will face.

Why Choose Emerson Bearing?

Emerson Bearing has been a trusted name in the bearing industry for decades. We specialize in precision-machined bearings designed to meet the highest standards of quality and performance. Whether you need ball bearings, ceramic bearings, roller bearings, or super precision bearings, we have the expertise and technology to deliver the right solution for your application.

Our commitment to excellence ensures that every bearing we produce is built to last. With a wide range of products and services, we’re here to support you from selection through installation and beyond.

Ready to find the perfect bearing for your needs? Visit our Contact Us page or fill out our Request a Quote form today. Let us help you achieve peak performance and reliability.

Medical Tantalum,Astm Medical Tantalum,Medical Tantalum Implants,Medical Tantalum Devices