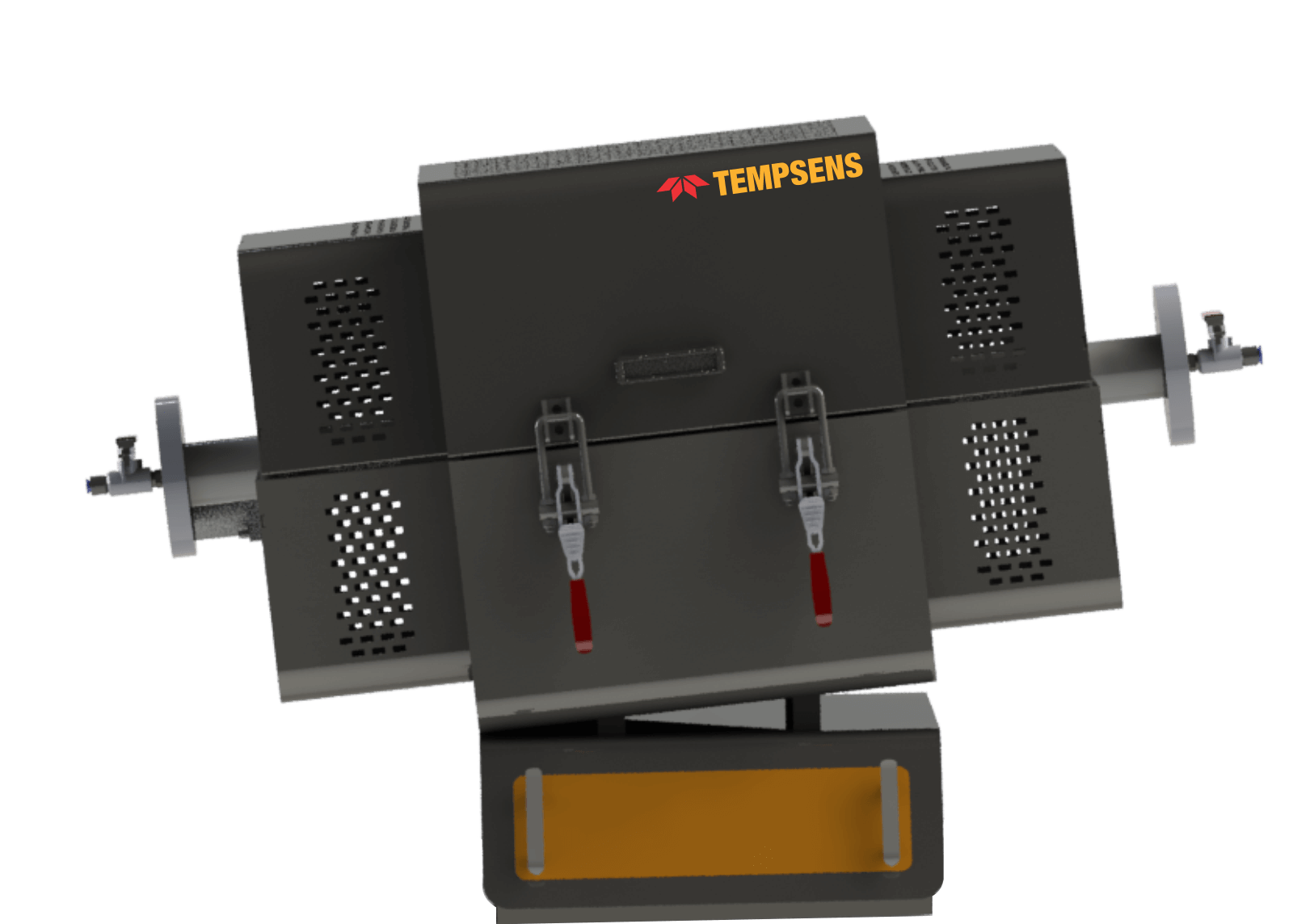

Rotary Tube Tilt Furnace

A Rotary Tube Tilt Furnace is a cutting-edge heating system designed to deliver precise and uniform thermal treatment for powders, granules, and other particulate materials. Unlike traditional static furnaces, this advanced unit features a rotating and tiltable tube that ensures even heat distribution and efficient material movement. The continuous rotation helps prevent clumping and uneven heating, making it ideal for applications where temperature consistency is critical.

Thanks to its dynamic design, the Rotary Tube Tilt Furnace can handle various particle sizes and types, from fine powders to larger granules. It's widely used in industrial processes like sintering, calcination, and carbon activation. The constant motion of the material inside the furnace improves thermal contact, reduces hot or cold spots, and enhances product quality. This makes it an essential tool for high-precision manufacturing environments.

The tilting feature adds another layer of flexibility, allowing operators to control material flow and adjust processing time based on specific requirements. This is especially useful when handling bulk materials, as it minimizes buildup and improves operational efficiency. The combination of rotation and tilt also supports both batch and continuous operations, offering scalability for small-scale testing and large production runs. Plus, the furnace can be equipped with advanced control systems for real-time monitoring and adjustment of temperature, atmosphere, and flow rates.

- Low RPM range 1–20 RPM: Ideal for delicate materials, ensuring even heat exposure without clumping or uneven heating. Offers precise control over material residence time.

- Tilt angle 6–15°: Adjusts material flow by altering gravitational effects, optimizing processing conditions for different applications.

- Gas purging & Vacuum atmosphere: Provides flexibility for processes like sintering, calcination, and annealing under controlled environments.

- Continuous & Batch operation: Supports both small-scale and large-scale production, making it adaptable to diverse needs.

- Max. temperature 1200°C: Suitable for carbonization, ceramic sintering, catalyst activation, and material drying.

- Split mechanism for easy loading: Reduces downtime and simplifies material changes, improving overall efficiency.

- Tube material: Quartz or Alumina: Selected based on application requirements for optimal performance and durability.

- Scraper bars for mixing: Ensures even material distribution and prevents sticking, enhancing thermal transfer and process uniformity.

Tailorization offered by Tempsens

- Multiple heating zones for precise temperature control.

- Customizable holding time based on tilt angle and material type.

- Internal scraper bars for improved mixing and material flow.

- Integrated input hopper with screw feeder for automated feeding.

- Gas purging and vacuum system for controlled atmospheres.

- Programmable PID controller with data logging and remote connectivity (RS-232/RS-485/Ethernet).

Recent Development: Tempsens Rotary Tube Furnace for Carbon Activation

At Tempsens, we have developed a specialized rotary tube furnace tailored for the carbon activation process. This furnace is designed to efficiently convert raw carbon-based materials—such as coconut shells or coal—into high-quality activated carbon. During the process, the furnace provides consistent heating for carbonization and then activates the material using an Argon atmosphere at temperatures up to 800°C. The continuous rotation ensures even exposure to heat and activating agents, which enhances porosity and surface area, resulting in superior adsorption properties. Our technology delivers reliable, scalable, and energy-efficient solutions for the carbon activation industry.

Applications

- Powder processing: Calcination, Sintering, Drying

- Material Synthesis: Ceramics, Nanomaterials, Advanced Materials

- Thermal Treatment of Chemicals: Catalysts, Reactions in Controlled Atmospheres

- Carbon Activation and Carbonization

- Metallic and Metallurgical Processes

- Pharmaceutical Powders

Advantages of Using Tempsens Rotary Tube Tilt Furnace

- Enhanced Mixing: Continuous rotation ensures better heat transfer and prevents material clumping.

- Improved Energy Efficiency: Uniform heat distribution leads to lower energy consumption and higher productivity.

- Ease of Discharge: The tilt function allows for smooth and automatic material removal, reducing manual labor.

- Customizable Design: Flexible options in tube material, length, and configuration to suit specific process needs.

For more details, visit our catalog at catalog/industrial-furnaces/laboratory-furnaces.html.

Fuel Pump is an essential component of machinery, designed to efficiently supply fuel to the engine. It is meticulously engineered to deliver a constant flow of fuel, ensuring optimal performance and reliability. This assembly comprises a high-quality pump, Filter, and other necessary components, all expertly integrated to provide seamless operation. It is a crucial part of the machinery fuel system, ensuring smooth and uninterrupted operation for maximum productivity. Jining BST company can provid various brand fuel pump, such as Cummins fuel pump, shantui fuel pump, komatsu fuel pump, CAT fuel pump, with high quality and reasonalbe price.

Fuel Pump,Fuel Injection Pipe,Fuel Transfer Pipe,Engine Fuel Injection Pipe

Jining BST Import and Export Co.,Ltd , https://www.komatsucatparts.com