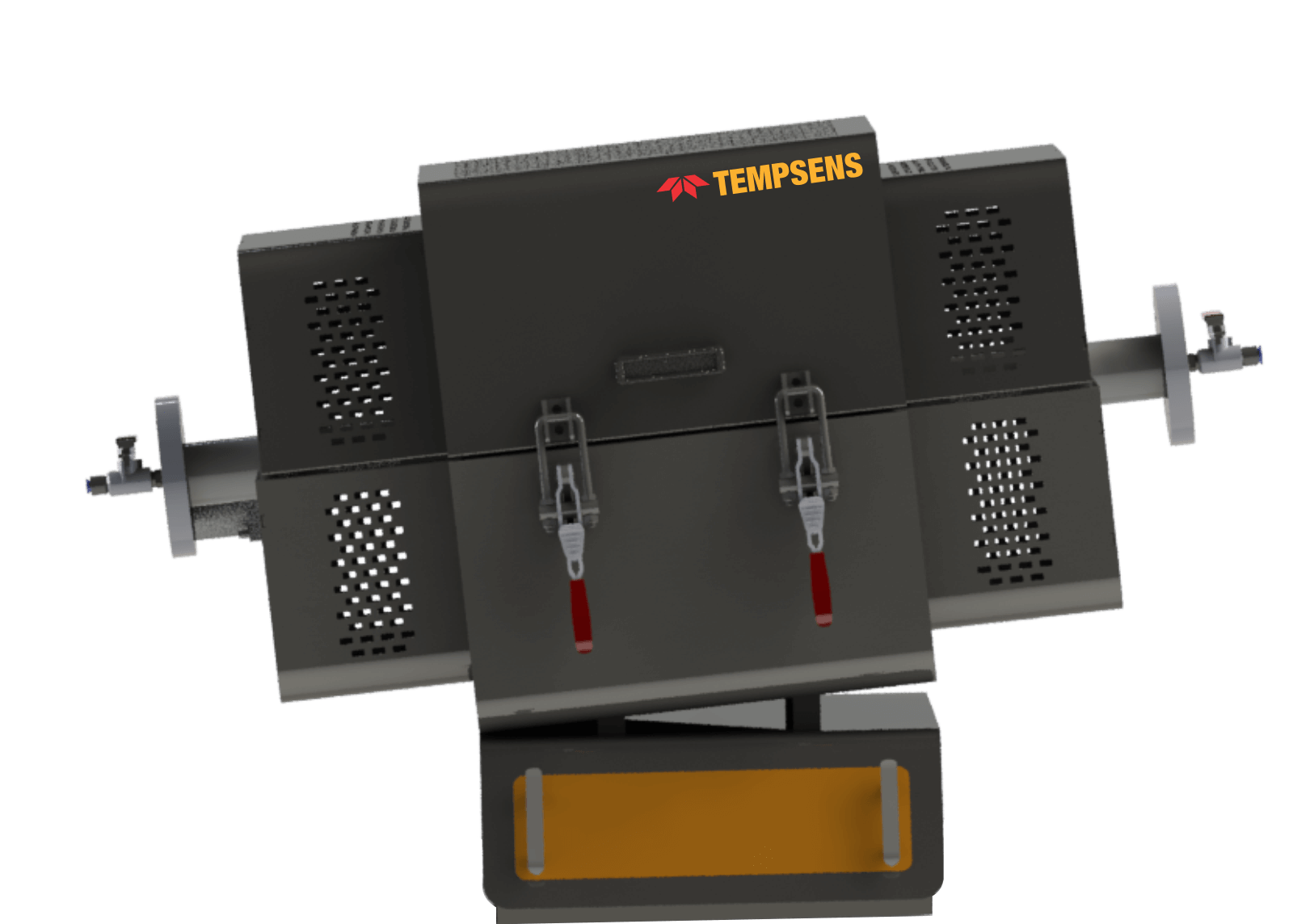

The Rotary Tube Tilt Furnace is a highly specialized piece of equipment designed for precise and consistent heat treatment of granules, powders, and other particulate materials. Unlike traditional static furnaces, this advanced system features a rotating tube that can also be tilted, offering improved heat distribution and more efficient material handling. The continuous rotation ensures that the materials inside are constantly in motion, enhancing thermal transfer and reducing the risk of clumping or uneven heating. This makes it particularly well-suited for applications requiring high temperature uniformity and process efficiency.

This innovative design allows the furnace to handle a wide range of particle sizes and material types, from fine powders to coarser granules. It is widely used in industrial processes such as sintering, calcination, and carbon activation. The constant movement of the material ensures that each particle receives consistent exposure to heat, which minimizes the formation of hot or cold spots—common issues in static systems that can lead to defects or inconsistencies in the final product.

The tilting feature adds an extra level of flexibility, enabling operators to control the flow of materials and adjust residence times as needed. This is especially useful when working with bulk materials, as it helps prevent buildup and improves overall operational efficiency. The combination of rotation and tilt makes the Tempsens rotary tube furnace ideal for both batch and continuous operations, offering scalability for use in pilot projects or large-scale production. Additionally, the system can be integrated with advanced control technologies, allowing for precise management of temperature, atmosphere, and material flow, making it a powerful tool for high-performance industrial applications.

- Low RPM range 1-20 RPM: Ideal for delicate materials, ensuring even heat exposure without clumping. Offers precise control over material residence time, suitable for both sensitive and robust processes.

- Tilt angle 6-15°: Allows adjustment of material flow by altering gravitational effects, improving processing efficiency.

- Gas purging & Vacuum atmosphere: Provides flexibility for various applications like sintering, calcination, and annealing.

- Continuous & Batch operation: Supports both small-scale testing and large-scale production.

- Max. temperature 1200°C: Suitable for carbonization, ceramic sintering, catalyst activation, and drying.

- Split mechanism for easy loading: Reduces downtime and ensures smooth operation during frequent material changes.

- Tube material: Quartz or alumina, chosen based on application needs for optimal performance.

- Scraper bars for mixing: Prevents sticking and ensures uniform heat distribution during rotation.

Tailorization offered by Tempsens

- Multiple heating zones

- Custom holding time based on tilt angle

- Scraper bars for proper mixing

- Input hopper with screw feeder

- Gas purging and vacuum system

- Programmable PID controller with RS-232/RS-485/Ethernet and data logger software

Recent Development of Tempsens Rotary Tube Furnace for Carbon Activation Process

At Tempsens, we have developed a specialized rotary tube furnace tailored for the carbon activation process. Designed for precision and efficiency, this furnace is ideal for converting raw carbonaceous materials—such as coconut shells or coal—into high-quality activated carbon. During the process, the furnace provides consistent heating for carbonization, followed by activation using an Argon atmosphere at temperatures up to 800°C. The continuous rotation ensures uniform exposure of the material to heat and activating agents, resulting in enhanced porosity and surface area. This leads to superior activated carbon with high adsorption capacity, meeting the needs of various industrial applications.

Applications

- Powder processing: Calcination, Sintering, Drying.

- Material Synthesis: Ceramics, Advanced Materials, Nanomaterials.

- Thermal Treatment of Chemicals: Catalysts, Reactions in Controlled Atmospheres.

- Carbon activation and carbonization.

- Metallurgical Processes.

- Pharmaceutical powders.

Advantages of Using Tempsens Rotary Tube Tilt Furnace

- Enhanced Material Mixing: Continuous rotation improves heat transfer and prevents clumping.

- Improved Heat Efficiency: Uniform temperature distribution reduces energy consumption.

- Ease of Discharge: Tilt function facilitates smooth material removal without manual effort.

- Customization Options: Flexible design, including tube material and length, to suit specific process requirements.

For more details, visit our catalog at catalog/industrial-furnaces/laboratory-furnaces.html.

The company provides high quality bulldozer parts and Excavator Parts that are designed to meet international standards. All of our products have undergone strict quality control protocols to ensure they maintain the highest standards.

Our advantage lies in:

1. High-quality products: Our products undergo strict quality control to ensure they are maintained to the highest standards.

2. Competitive prices: Our products are reasonably priced, which can help customers reduce costs and increase profits.

3. Timely transaction: We have a large inventory and can quickly trade payment products to meet customer needs.

4. Professional service: Our sales staff are experienced and can provide professional advice and technical support to help customers solve problems.

Dozer Parts,Transmission Dozer Parts,Dozer Gearbox Parts,Bulldozer Gearbox Parts

Jining BST Import and Export Co.,Ltd , https://www.komatsucatparts.com