Knowing how to use a product properly can make a huge difference in its performance and lifespan. For example, knowing how to maintain cast iron pans properly can make them last longer. With electric motors, understanding the factors that affect motor life is the first step to extending its longevity and reducing costs over time.

What does "end of life" really mean?

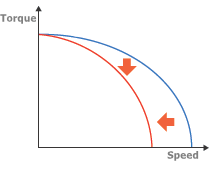

End of life typically refers to when a product no longer functions as intended. But what exactly does that mean in practical terms? It means that the motor can still run, but it fails to meet the speed, torque, or accuracy specifications outlined in its documentation. If a motor can't perform as expected, it's essentially "dead" for its intended purpose.

As a motor ages, factors like wear and tear cause its performance to decline. Torque and speed may gradually reduce, making it less effective over time.

What are the main factors that influence motor life?

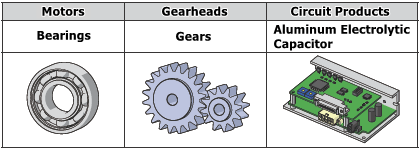

The lifespan of a motor often depends on the first component that fails. The three most common components prone to failure are bearings, gears, and circuit elements such as drivers and controllers.

Bearings

|

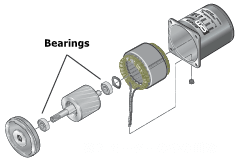

Bearings are essential components that help reduce friction between moving parts and support the load within a motor. If bearings fail, the motor stops working entirely. They are therefore considered critical parts of the system. |

|

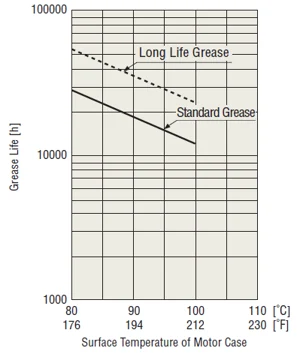

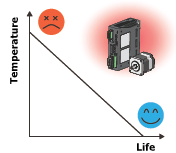

Standard motor operating life is estimated based on bearing grease life, which is affected by temperature. Exceeding the motor’s specifications, such as radial (overhung) load and axial (thrust) load, can also lead to a shorter life. Motors with long-life bearing grease can extend their life to about 10,000 hours of operation. |

|

Gears

Gears are used to either reduce the speed of a motor and increase torque. Torque is multiplied by the gear ratio, while speed is reduced accordingly. Like bearings, gears handle the load directly and can eventually wear out—especially under heavy or impact loads. When they do, the motor may still work, but backlash and noise may exceed acceptable limits.

Circuit Products

Circuit products include drivers and controllers, which supply power and logic to motors. Components like electrolytic capacitors in these circuits can fail due to high temperatures. As a result, the lifespan of circuit products is largely determined by the life of these capacitors.

| TIP: How does temperature affect life exactly? | ||

|

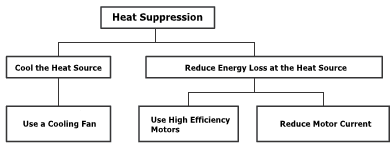

How can heat be controlled?

To manage heat effectively, there are two main approaches: cooling the heat source or reducing the amount of heat generated. Cooling methods include using fans, mounting on larger metal plates for better heat dissipation, or even liquid cooling systems. Reducing the operating temperature helps prolong the life of motor components, especially the bearing grease. It can also improve the duty cycle of the motor. I’ve supported applications where water-cooled jackets were used to push a stepper motor’s duty cycle close to 100%.

The second approach is to minimize energy loss at the motor. Since energy loss generates heat, reducing this loss also lowers the temperature. This can be achieved by using high-efficiency motors or continuous-duty motors. For stepper and servo motors, lowering the current can also help reduce heat. However, current is directly related to torque, so it's important to find a balance—reduce current to the lowest level that still provides sufficient torque while keeping the motor cool.

Thanks for reading! If you want to learn more about how temperature affects service life, rated life for different products, or how to calculate service life, check out our technical reference section. You’ll find detailed explanations there.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '37366249-cf39-4d82-b445-cf0ca1d9d6a6', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '37366249-cf39-4d82-b445-cf0ca1d9d6a6', {"useNewLoader":"true","region":"na1"});

Interested in cooling fans, high-efficiency motors, or ways to reduce current? Contact our knowledgeable technical support engineers today for personalized advice and solutions tailored to your needs.

candle silicone mold,customs candle mold with silicone,silicone candle mold

Meichen(Hebei) Technology.,Ltd , https://www.yuyilang.com