Ever wondered why your car can't run without certain parts? The alternator is one of those critical components. It plays a vital role in keeping your vehicle running smoothly by generating electricity and charging the battery at the same time.

If you're curious about how alternators work, what they look like, or how to tell if yours is failing, this guide has everything you need to know.

What Is An Alternator?

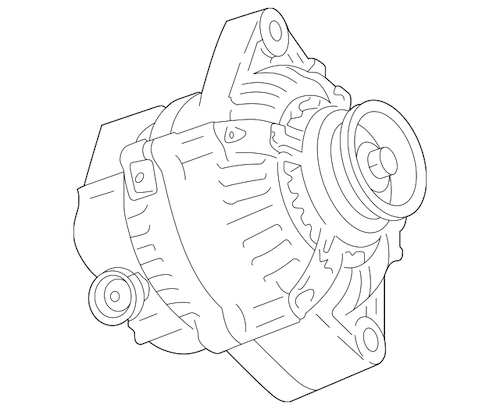

Toyota alternator #27060-74750-84: for 1998-2000 RAV4s

The alternator is attached to the engine via a pulley and acts as a small generator that powers all the electrical systems in your car. This includes things like:

- Dome lights

- Dash panel

- Heat/AC fan

- Stereo system

- Power mirrors and seats

- Brake lights

- Headlights

- Turn signals

You might be wondering, "If the battery powers these, why do I need an alternator?" That's a great question. While the battery provides power when the engine is off, the alternator keeps it charged while the engine is running, ensuring your car stays powered up throughout your drive.

What Does An Alternator Look Like?

A Toyota alternator is roughly the size of a grapefruit and weighs around 6 pounds. Here’s what it typically looks like:

Although the design may vary slightly between models, all alternators share some key features:

- Plenty of ventilation holes to prevent overheating

- A rotor inside that spins to generate electricity

There are four main parts inside an alternator:

- Stator

- Rotor

- Diode

- Voltage regulator

How Does An Alternator Work?

As soon as you start your car, the alternator begins working to charge the battery and power the electrical systems. Here's a step-by-step breakdown:

- The ignition switch is turned on.

- The engine starts running.

- The drive belt turns the alternator pulley.

- The rotor spins, creating electricity through electromagnetism.

- This electricity flows through the stator and is converted from AC to DC by the diode.

- The DC current is then sent to the battery via the voltage regulator.

- The battery powers your car's electrical components.

Can An Alternator Fail?

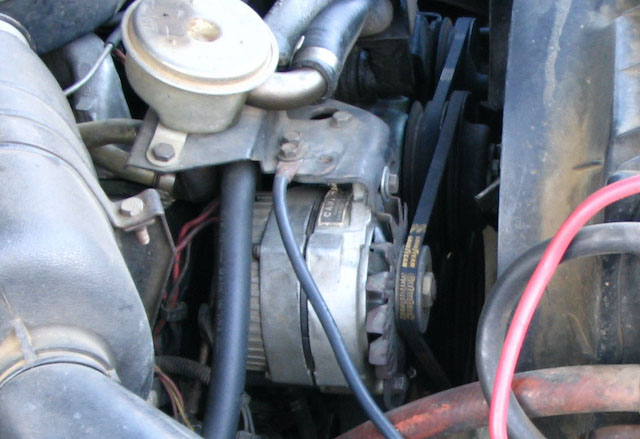

An alternator in action. Source: Phasmatisnox via Creative CommonsÂ

On average, an alternator can last up to 100,000 miles. However, over time, various parts can wear out, such as:

- Alternator pulley

- Diodes

- Voltage regulator

- Stator

- Bushings

- Coil

- Bearings

Early failure can also happen due to improper installation or mishandling. For example:

- An alternator pulley could break if installed too tightly.

- A faulty refurbishment might lead to failure.

- A new alternator could fail if it was dropped before installation, causing internal damage.

How Much Does A New Alternator Cost?

A brand new OEM alternator can range in price from $150 to $900, depending on the model. If you're looking to save money, consider a remanufactured or refurbished unit, which often offers good value without sacrificing performance.

One of the best ways to get a great deal is to purchase online. Unlike dealerships, which often add a large markup, online retailers can offer competitive pricing thanks to lower overhead costs. We even offer wholesale prices and a wide selection of genuine OEM alternators—check out our catalog today!

Written by Jason Lancaster

PP sheet is made of PP resin through the process of brewing, calendering, trimming, etc. It has light weight, bright and calm surface, good heat resistance, high mechanical strength, excellent chemical stability and electrical insulation. , Non-toxic, etc., can be made into beverage cups, food boxes and other daily necessities after thermoforming.

main feature:

1. It can be used for a long time at 100℃ and can withstand high temperature bacteria treatment at 121℃. It has outstanding moisture-proof performance and reliable hygienic performance. It is widely used in food packaging. With excellent folding performance, it can be made into stationery clips, boxes, etc.

2. If classified according to the performance of the material, it can be divided into

Common materials, environmental protection materials, cold-resistant materials, anti-breaking materials, conductive materials and anti-static materials, etc.

3. If classified according to the effect of the product, it can be divided into

Transparent materials, color materials, gold-plated materials and flocking materials, etc.

4. Density 0.96~0.98g/cm

Anti-static materials usually use PVC, PP, PS and PET materials, of course, PE materials can also be used; conductive materials usually use PP, PS and PET materials; and flocking usually use PVC and PS materials.

Flocking (flocking) materials and products:

Flocking (flocking) material is a kind of material that has been used more in recent years. It mainly uses PVC and PS materials as the negative film, and planting various colors of fluff on the sheet. It is mainly suitable for some relatively noble, beautiful and generous products (such as cosmetics). Inner support, mobile phone inner support, foreign wine inner support, glasses case, etc.).

Polypropylene Sheet,Polypropylene Plastic Sheets,Pp Sheet For Thermoforming,Polypropylene Sheet Roll

Shandong Top Leader Plastic Packing CO., LTD , https://www.sdzlplastic.com